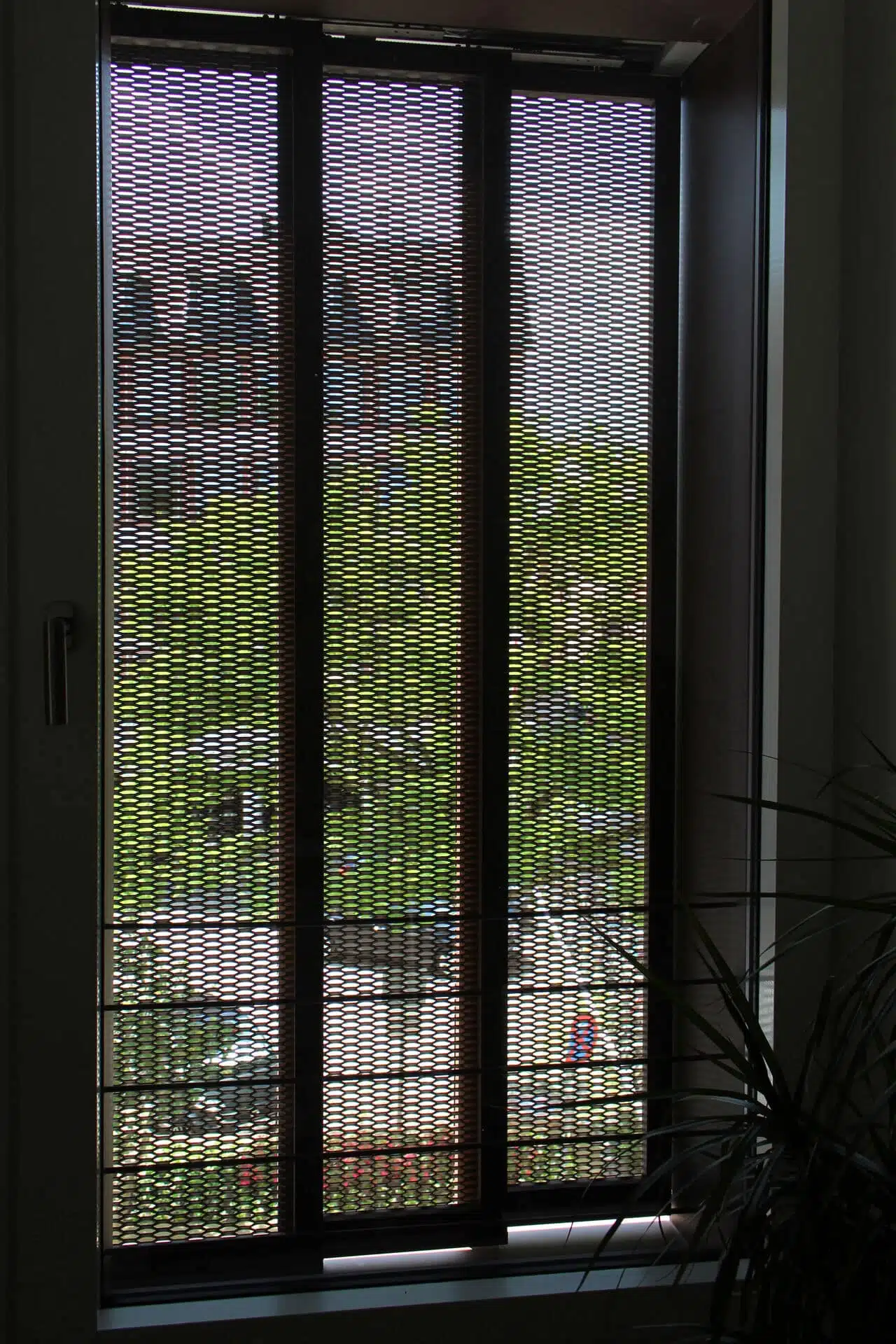

Sliding shutters with expanded metal functional and visually appealing

Expanded metal is a popular material for sun protection and façade design. By “untwisting” the sheet metal, a multitude of “mini-slats” are created that provide ideal sun protection without completely blocking the view outside.

Like all slats, the expanded metal takes advantage of the fact that the intense midday sun shines on the building from above or from a very high angle. The expanded metal, which is also inclined, keeps out this steep and intense radiation. However, indirect light can still enter through the perforations, i.e. the openings in the expanded metal, and it still allows a discreet view through the expanded metal.

Filigree design of the façade with sliding shutters made of expanded metal.

In addition, the loosening effect of expanded metal is also an absolute eye-catcher visually. Modern, without appearing obtrusive, large surfaces, but also, as in this example, small details, can be lovingly designed with expanded metal.

Another advantage of customised expanded metal is that public office buildings usually require not only sun protection but often also glare protection, which is often achieved with additional interior measures. This can be combined here due to the exclusion of direct sunlight, but the letting through of diffuse light.

Circumferential aluminium frames

Another interesting detail was used here as an integration into the rendered façade: a circumferential frame made of aluminium. It integrates the sliding shutters into the overall façade both visually and functionally.

Metal frames are an outstanding design element in architecture. They break up the façade and stand out from the mass of plastered reveal frames. Not so easy in detail: it requires precise planning, coordination with other trades and clean execution. As an experienced craftsman, we plan, deliver and install metal window frames from a single source.

If, as in the example shown here, it is possible to integrate the sun protection and the fall protection in the necessary areas, both functional and aesthetic requirements can be equally satisfied by a metal window frame.

Precisely fitting window frames

Window frames are usually made of aluminium sheet or semi-finished products such as angle profiles. Folded over, welded and ground in the corners and then powder-coated, they are mounted precisely on the window using special brackets. Depending on the design of the façade, the transition is made with the help of connecting profiles or a shadow joint, for example to a plaster façade.

Prefabricated and quickly assembled

The complete construction element consisting of frame and sliding shutter could already be prefabricated in the factory. This meant that the sun protection and the reveal cladding could be installed on site in a very short time.

The planning was carried out in intensive consultation with the monument protection authorities – front-mounted sun protection systems were not permitted, so the sun and glare protection was integrated into the four-sided, slightly projecting frame in accordance with historical window jambs. In this way, the system finds a contemporary and at the same time functional implementation, yet the circumferential shadow gap self-confidently sets the elements apart from the historic building stock, as a return of the house, which has already been converted many times, to a uniform time horizon was not desired.

Rusty brown colour as a historical context

Today, powder coatings are state of the art in façade construction. In addition to the classic solid colours, outstanding (colour) accents can also be set here.

In this example, a rust-brown colour was chosen as a powder coating to create a reference to the historical context of the building. The uniformity of the surface ensures that there are no nasty surprises.

Hangings with flat fillings

Hangings with flat fillings