Customised skylight enables conversion of old industrial hall

As a transition between locksmith’s shop and warehouse, the hall with a gable roof was only slightly utilised. So there would have been space for offices. But the architecture of an industrial hall does not meet the requirements of modern offices.

In addition, the company attaches great importance to the working atmosphere. The requirements were: The employees should feel comfortable in a pleasant ambience with lots of light and air.

A roof ridge with windows brings light and space

The Hulverscheidt + Kindler planning team decided to use the large roof area to light the rooms. In doing so, they did not rely on standard roof windows. Over-ridge glazing was to break up the roof and achieve the desired lightness.

The engineers found the right partner in Baier. For the project, the metal construction company was able to combine two of its passions:

- the planning, production and installation of individual window systems.

- Sales and installation of skylight windows and the production of matching skylight shutters

Something for bright minds: skylight in the roof ridge

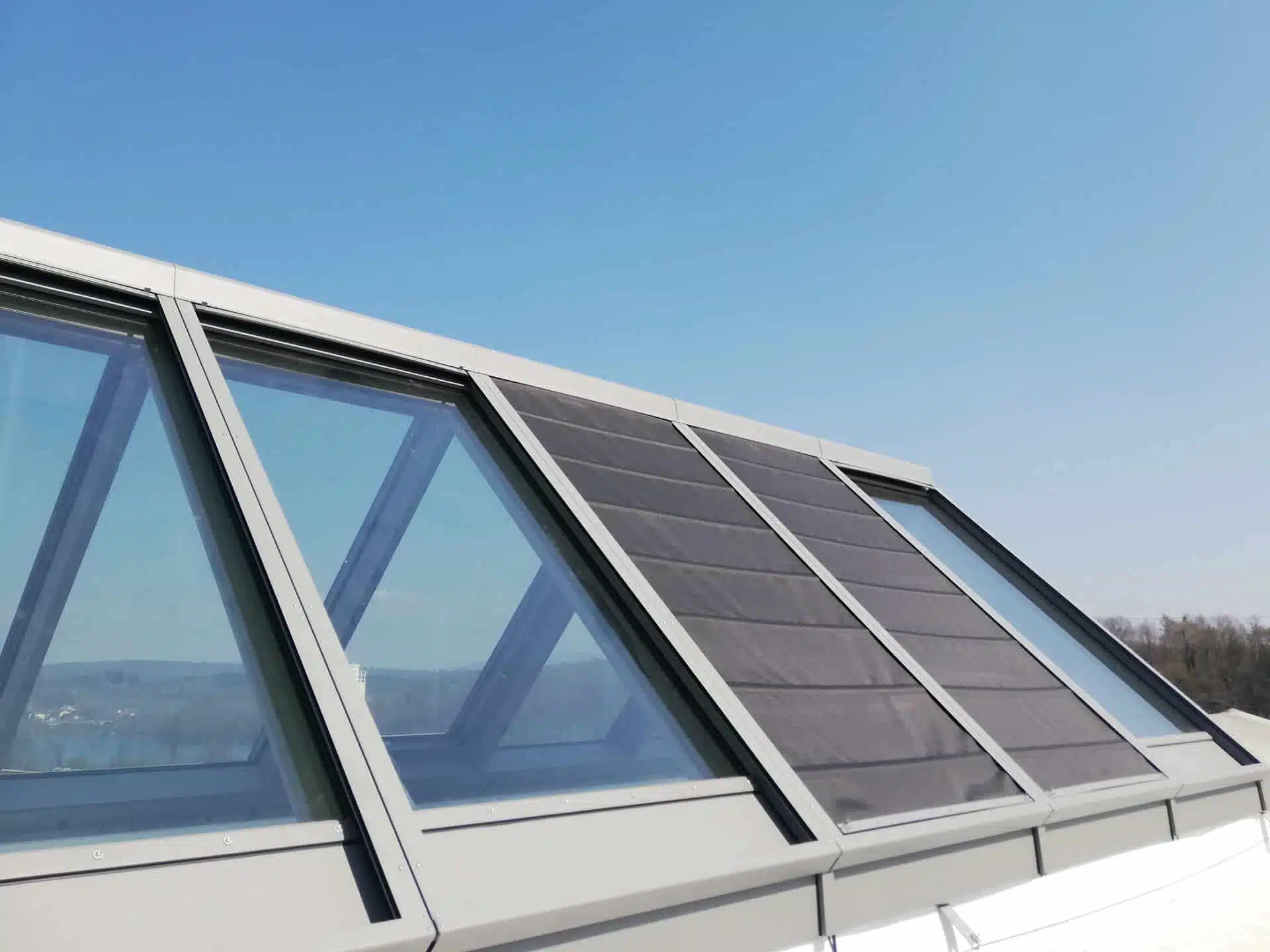

For the conversion of the old factory building, Baier developed a 10-metre long and 4-metre wide skylight with an inclination of the two legs of 45° each.

The basis is the C 50 HI aluminium profile, which Baier also uses for the construction of architecturally sophisticated mullion-transom façades. In this case, Baier used it to make a piece of roof ridge at an angle of 90 degrees.

The ridge turret is divided into 16 glazed compartments per leg. The overhead glazing requires a high safety standard, which Baier meets with safety glazing.

Two of the skylight windows can be opened remotely for ventilation. Baier used its high-quality drive technology for this.

Genuine customisation – skylight and textile screen roller shutters

All window areas can also be shaded with screens using a motor. Baier manufactured the corresponding roller shutters for this purpose. This prevents the new offices from heating up and ensures a pleasant working atmosphere.

The entire roof window system was placed on two 10-metre-long glued beams and the gable ends were closed with a wooden construction. This shows the flexibility of the company to also process “non-technical” materials.

The entire construction element was lifted as one piece onto the open roof by crane and assembled there by Baier’s experienced craftsmen. A steel construction absorbs the forces and serves as a support for the component.

Just-in-time production and delivery – not only the component is customised

One might think that the planning, production and installation of this unique roof window system was a major challenge for Baier. But for the Baier expert in charge, it was more a part of everyday life – even if it was a particularly interesting task.

The real challenge lay in the more than tight schedule. Baier had just four weeks from the first rope to the installation. “The profiles were still warm from coating when we started working on them.” Says the employee in charge at Baier.

The effort was worth it. The new skylight made it possible to transform an unused area into new, high-quality office space – without sealing any more surface. The interior design with its industrial look gives a hint of the building’s origins.

If you too would like to tap into new architectural potential with a customised window system, please contact us. We will be happy to advise you.