Power cut-off

The microprocessor-controlled power cut-off, present in all our drives, ensures that the maximum force the drive exerts is limited. The control unit knows when the force becomes too high and switches off through an overcurrent and, therefore, power measurement. This technology enables the drives to be operated without additional safety devices such as light barriers or emergency stops. The required forces are determined automatically during set-up.

Soft stop

After commissioning, the control unit knows the duration of a movement and can slow down shortly before the end. This is aesthetically pleasing and protects the mechanics.

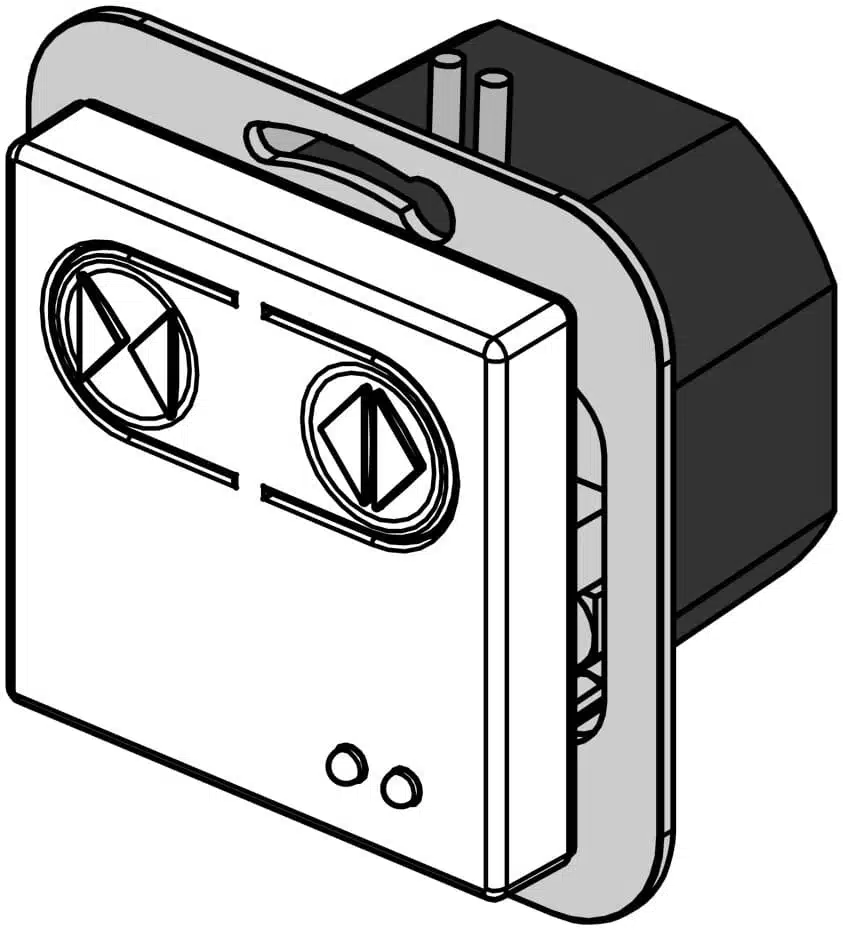

24V flush-mounted unit

The 24V flush-mounted unit is a fully integrated unit consisting of a power supply unit, control unit and push-button cover that fits into a flush-mounted box. The power supply unit disappears into the flush-mounted box. The control unit remains accessible with the removable push-button cover.

Wireless control is effortless with this variant: a push-button cover with an integrated wireless module is plugged in without additional wiring. Any number of hand-held transmitters can be programmed into the wireless receiver by pressing a button.

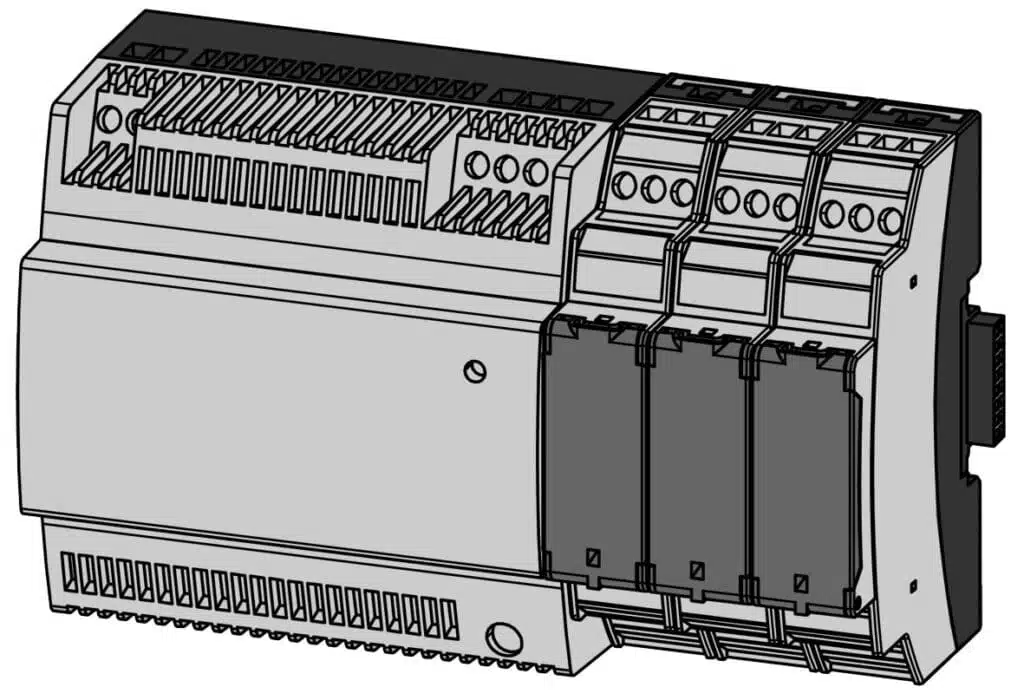

24V rail-mounted unit

The 24V rail-mounted device is designed for installation in the control cabinet on standardised mounting rails according to DIN EN 50022, with a width of 35mm (a.k.a. top-hat rails). The power supply unit is selected separately, depending on the number of control units used.

A convenient feature of using this variant is connecting the control units through so-called mounting rail connectors. This reduces the cabling effort enormously. The group control unit can combine several control units in individual, group and overall control.

Further functions and benefits of the 24V technology

Settings for further functions

Different speeds can be selected via DIP switches and switched between semi-automatic and dead man functionality. In semi-automatic mode, the drive continues to move even if the control button is no longer pressed. This continues until an impulse is given in the opposite direction or the drive runs into an obstacle or the end. In dead man’s mode, the drive switches off immediately when the control button is released.

Simplest cable installation

No special cables or plugs are necessary for the use of the motor and control unit. A 230V power supply at the control unit and a 2-wire cable of sufficient cross-section between the motor and the control unit are enough.

Alternatively, additional potential-free buttons can be connected using a 3-wire cable as described above.

Connection of additional devices

The connection of additional devices such as wireless remote controls, light, rain and wind sensors, and external push-buttons is possible without further effort. For more details, see Accessories.

All types of controls are possible using the potential-free contact: on-site bus system via a potential-free actuator, additional push-button or conventional group control, installation in the control cabinet, and much more are not a problem thanks to the standard potential-free open/stop/close input.

24V technology for maximum safety

Since the complex and high-voltage parts of the 24V motor technology are located inside, you always have access to the control unit for service and maintenance work. The use of low tension in the outdoor area ensures maximum safety and the simplest connection.

230V direct connection

If a 230V connection is already prepared, our 230V direct connection motor can be used. The control unit is integrated into an additional housing directly in the engine, encapsulated and therefore protected from moisture and damage.

Connection variants

Different connection variants, four-, three- or two-wire, give you every option, regardless of which cabling has been provided. With the four-wire connection with L, N, Open and Close, you can control both push-buttons and integrated wireless. If only three wires are available, connect N, Open and Close. A switch can operate the motor. If you only have one power cable or one socket from which L and N come, the engine can be supplied via these two wires and controlled by wireless.